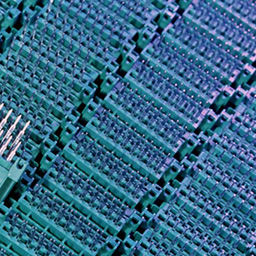

Plastics Injection

By realigning our focus into a highly innovative and value-added sector, we are ready to take on both the challenges and opportunities that lie ahead. Our offerings now include: Early supplier designing services, tooling manufacturing, Spray Lines, Anodizing, Vacuum Chamber deposition, Co- molding, CNC machining, Plastic Injection and Rubber compression. By offering “end-to-end” manufacturing service, clients can greatly reduce processing costs.

With the technical roadmap firmly in place, SinCo formulated a technique called co-molding technology. This is the process of begin able to mould and manufacture Rubber with different material substrates. Each of these substrates serves a different engineering purpose. For example, the soft nature of Rubber makes it an ideal outer shell or skin of the product as it can provide more grip, this is opposed to Plastics which is inherently harder and is manipulated and manufactured on a completely different platform and methodology.